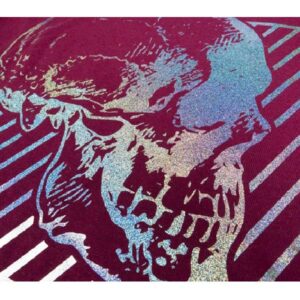

Glossy Heat Transfer Vinyl – Thermoflex Plus

When you want a design that has an extra bit of shine, ThermoFlex Plus glossy HTV is the clear choice. It’s flexible and easy to work with, and it makes your projects look unique and professional.

Description

ThermoFlex Plus is one of the most popular heat transfer vinyl brands in the industry. It’s made from a special polyurethane blend that gives it an ideal amount of flexibility and strength. This means that it can be used on clothing, canvas bags and a number of other fabric projects that will be subject to heavy use.

Unlike other heavy-duty vinyls, ThermoFlex Plus Glossy is soft to the touch and does not crack or cause the fabric to pucker after application. When applied correctly, the texture of the design is nearly impossible to distinguish from the texture of the fabric.

This glossy heat transfer vinyl is available in four colors, and it can be applied to many of the most common fabrics, including:

- Cotton

- Polyester

- Cotton/polyester blends

- Acrylic/polyester blends

- Lycra

- Spandex

- Wool

- Linen

Please note that this glossy HTV will not adhere to nylon. It is also important to note that, due to the nature of the finish, it is not recommended to attempt to add layers on top of this vinyl. However, you can layer other colors underneath it.

Additional Details

- High-gloss finish

- 100 microns thick

- Sticky carrier for simple repositioning

- Available in sheets and rolls

- Flexible and durable

- Easy to weed

Additional information

| Color | 9301 Glossy Red, 9236 Glossy Black, 9100 Glossy White, 9843 Glossy Gold |

|---|---|

| Size | 15 In x 1 Ft, 15 In x 1 Yd, 15 In x 5 Yd, 15 In x 10 Yd, 15 In x 15 Yd, 15 In x 30 Yd |

Application Instructions

- Create your design with your favorite graphics software, and select “mirror image.”

- Before cutting your design, load the vinyl into your plotter, adjust the settings and perform a test cut.

- Once the settings are correct, cut your design in mirror image for proper transfer.

- Remove any excess film from the carrier before you position your design.

- Carefully position your design on the fabric, and place a Teflon sheet between the heat plate and the carrier. The Teflon acts as a buffer to protect your design from rolling up or sticking to the press.

- Heat the press to 330 degrees Fahrenheit, and apply firm, even pressure for 15 seconds.

- Peel warm, but you should allow at least 10 seconds of cooldown before you begin peeling.

Application Tips

- – Wash and dry your garments without fabric softener prior to vinyl application.

- – For shimmery fabrics, dazzle cloth and shiny polyester, gently blot the desired area with isopropyl alcohol before application. This allows better, more even penetration of the adhesive.

- – Wait at least 24 hours before washing the fabric after vinyl application.

- – Garments can be washed in warm or cold water and tumble dried on regular heat settings. To extend the life of the design, it’s recommended to turn the garment inside out before washing.

- – Do not bleach fabrics.

- – Dry cleaning is OK